Tasks of energy management software

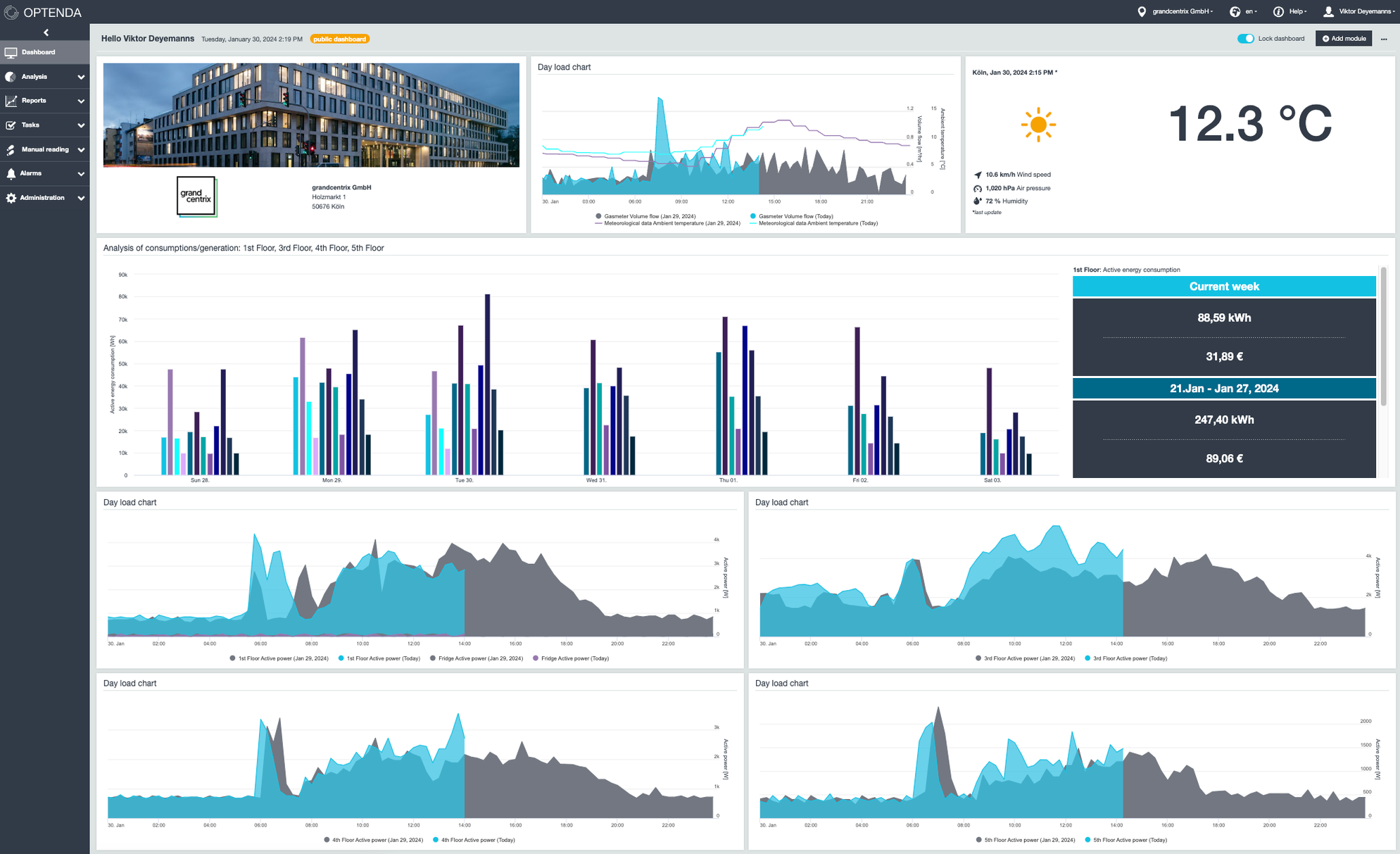

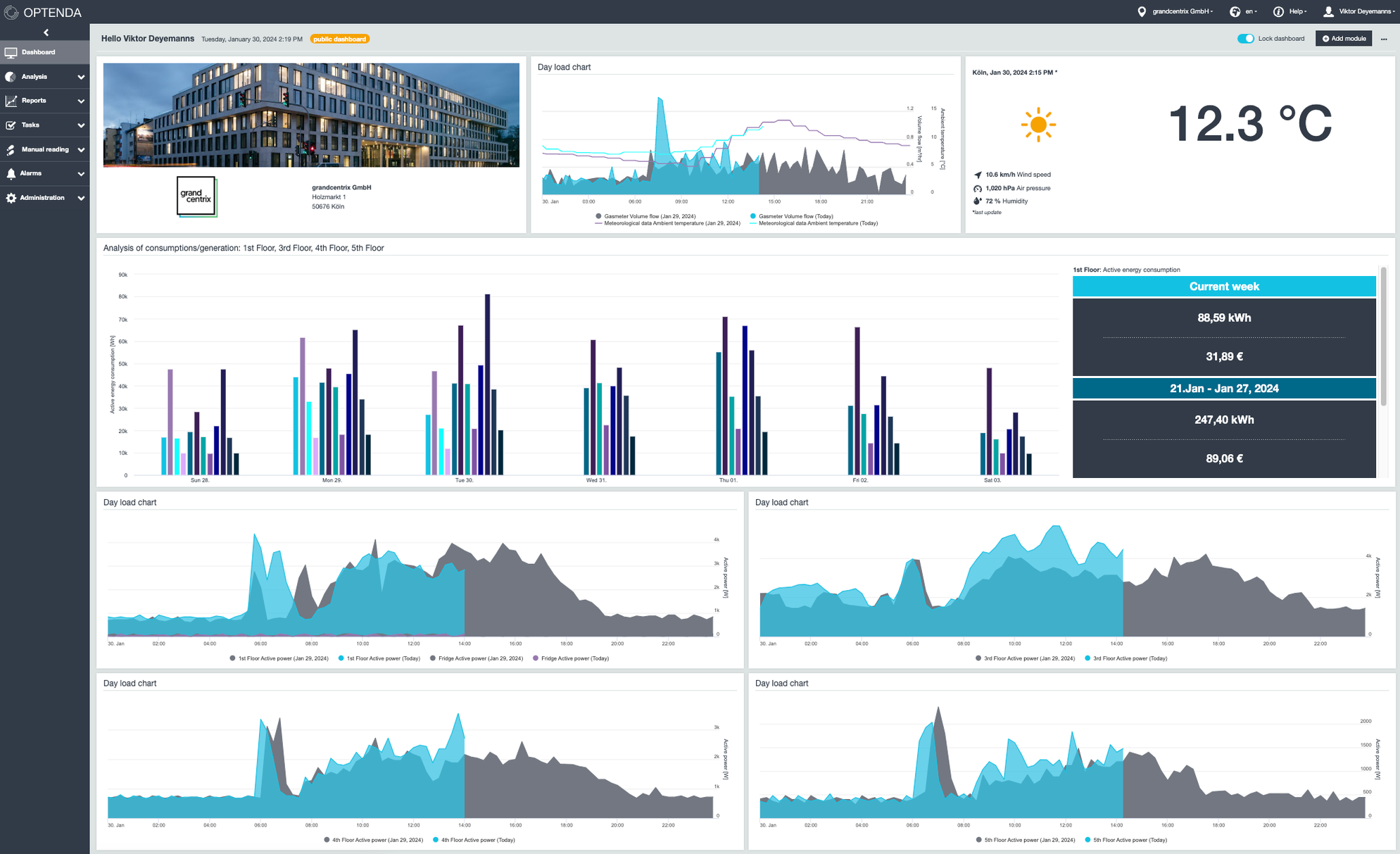

Energy management software centrally documents and visualizes all consumption data available to the platform. The resulting transparency allows consumption to be easily monitored, analyzed and optimized through appropriate measures. Companies use this software as a central tool for operating their energy management. The characteristics of the analyses and the data required for them can be very individual, which is why the software should offer a high degree of individualization in this context.

With OPTENDA’s Energy Monitor, energy consumption can be easily visualized on a dashboard according to individual requirements. There are also other preconfigured dashboards and options to carry out relevant analyses efficiently. The online platform can also be used to create individual reports and to document and track measures. These tools serve as support for operational energy management in the company. The platform works with data from the measuring devices that record the energy consumption of downstream consumers. The data can be imported manually so that a physical reading would also be possible. However, it is advisable to connect the meters and create a digital metering infrastructure to ensure that the software can be used consistently and cost-effectively in the long term.

The platform already natively supports many meters and gateways, but also has a universal connection option for transmitting data via MQTT.

Connecting the measuring devices

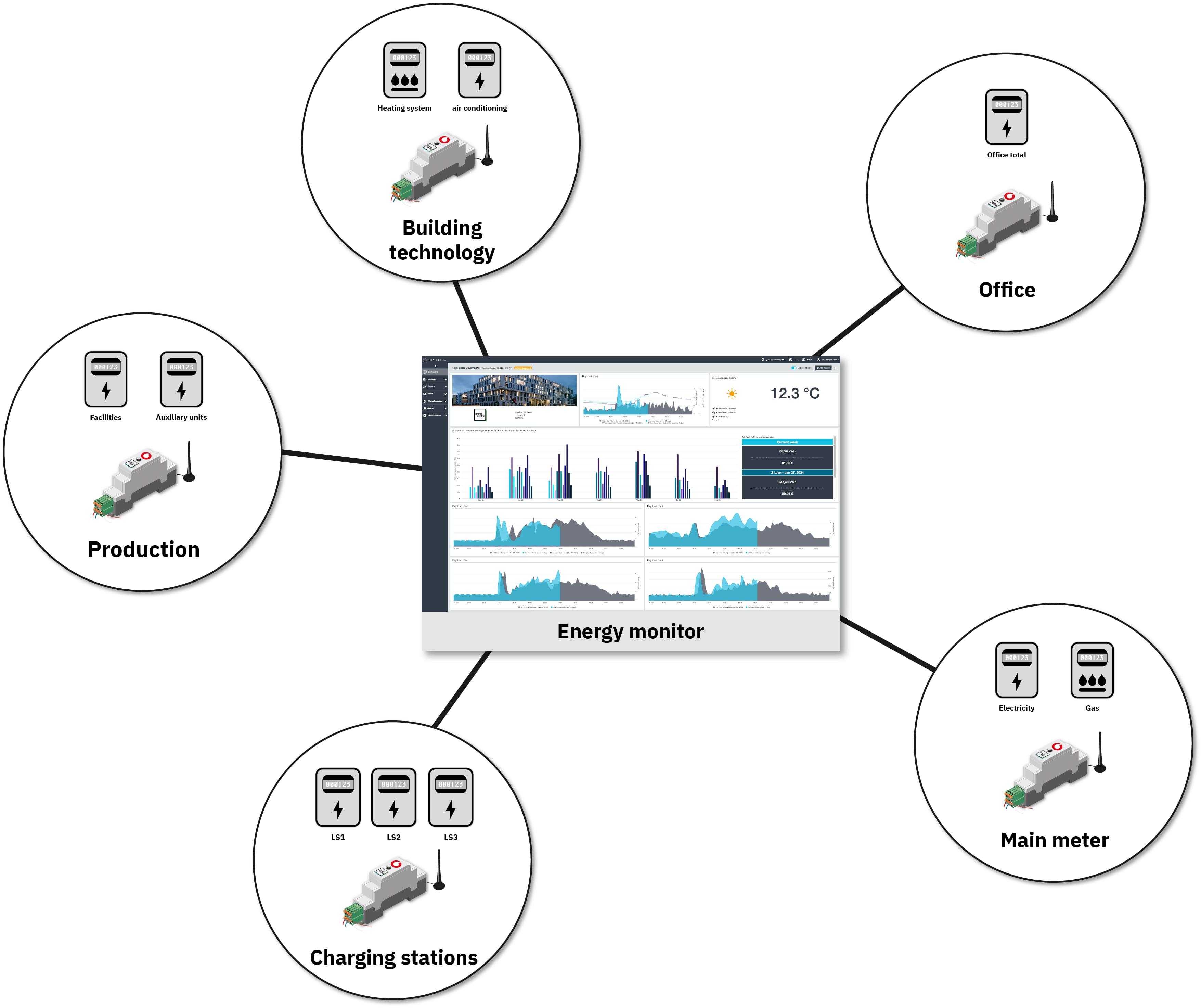

With Modbus Cloud Connect, these energy meters can be connected to transmit consumption data to OPTENDA’s Energy Monitor.

In order to carry out a meaningful analysis, it is necessary to perform granular measurement (submetering) in order to separate sub-areas locally or categorically. Special systems, such as a building’s heating or cooling system, often offer potential savings and should therefore also be able to be monitored in isolation.

Due to Modbus Cloud Connect it is easy to connect your devices. This means that both connecting new measuring devices and integrating existing measuring devices (retrofitting) is quick and easy. With a width of 1 TE (subunit), the required installation space in the distribution box is minimal, so that very little additional space is needed in existing installations. Thanks to the integrated NB-IoT/LTE-M modem, no local infrastructure is necessary for a data connection. A connection is also possible under difficult conditions, such as in basements. Meters that do not have a Modbus RTU interface can usually be connected to the Modbus Cloud Connect as required using additional hardware or converters. We have already reported on some combinations (Infrared and ZFA) as examples in our blog. This also includes mechanical meters (Retrofit via pulse interface), which can often be digitized in a retrofit using pulse transmitters in conjunction with a Modbus-capable pulse meter.